علم الكيمياء

علم الكيمياء

الكيمياء التحليلية

الكيمياء التحليلية

الكيمياء الحياتية

الكيمياء الحياتية

الكيمياء العضوية

الكيمياء العضوية

الكيمياء الفيزيائية

الكيمياء الفيزيائية

الكيمياء اللاعضوية

الكيمياء اللاعضوية

مواضيع اخرى في الكيمياء

مواضيع اخرى في الكيمياء

الكيمياء الصناعية

الكيمياء الصناعية |

Read More

Date: 24-9-2017

Date: 24-9-2017

Date: 26-5-2020

|

Properties and Uses of Polyethylenes

Polyethylene is an inexpensive thermoplastic that can be molded into almost any shape, extruded into fiber or filament, and blown or precipitated into film or foil. Polyethylene products include packaging (largest market), bottles, irrigation pipes, film, sheets, and insulation materials.

Currently, high density polyethylene is the largest-volume thermoplastic. The 1997 U.S. production of HDPE was 12.5 billion pounds. LDPE was 7.7 billion pounds and LLDPE was 6.9 billion pounds.

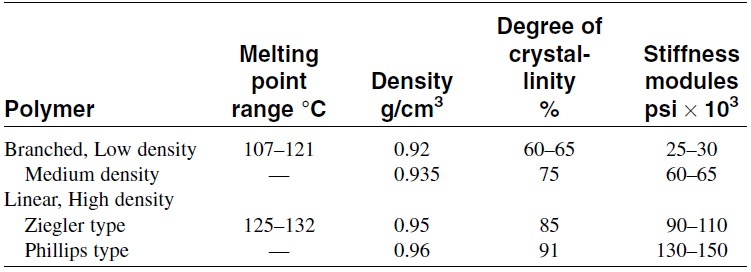

Because LDPE is flexible and transparent, it is mainly used to produce film and sheets. Films are usually produced by extrusion. Calendering is mainly used for sheeting and to a lesser extent for film production. HDPE is important for producing bottles and hollow objects by blow molding. Approximately 64% of all plastic bottles are made from HDPE. Injection molding is used to produce solid objects. Another important market for HDPE is irrigation pipes. Pipes made from HDPE are flexible, tough, and corrosion resistant. They could be used to carry abrasive materials such as gypsum. Table 1.1 shows the important properties of polyethylenes.

Table 1.1:Important properties of polyethylenes

|

|

|

|

علامات بسيطة في جسدك قد تنذر بمرض "قاتل"

|

|

|

|

|

|

|

أول صور ثلاثية الأبعاد للغدة الزعترية البشرية

|

|

|

|

|

|

|

مدرسة دار العلم.. صرح علميّ متميز في كربلاء لنشر علوم أهل البيت (عليهم السلام)

|

|

|