علم الكيمياء

علم الكيمياء

الكيمياء التحليلية

الكيمياء التحليلية

الكيمياء الحياتية

الكيمياء الحياتية

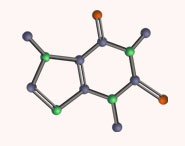

الكيمياء العضوية

الكيمياء العضوية

الكيمياء الفيزيائية

الكيمياء الفيزيائية

الكيمياء اللاعضوية

الكيمياء اللاعضوية

مواضيع اخرى في الكيمياء

مواضيع اخرى في الكيمياء

الكيمياء الصناعية

الكيمياء الصناعية |

Read More

Date: 11-9-2017

Date: 7-8-2017

Date: 19-1-2016

|

ACETALDEHYDE (CH3CHO)

Acetaldehyde is a colorless liquid with a pungent odor. It is a reactive compound with no direct use except for the synthesis of other compounds. For example, it is oxidized to acetic acid and acetic anhydride. It is a reactant in the production of 2-ethylhexanol for the synthesis of plasticizers and also in the production of pentaerithritol, a polyhydric compound used in alkyd resins.

There are many ways to produce acetaldehyde. Historically, it was produced either by the silver-catalyzed oxidation or by the chromium activated copper-catalyzed dehydrogenation of ethanol. Currently, acetaldehyde is obtained from ethylene by using a homogeneous catalyst (Wacker catalyst). The catalyst allows the reaction to occur at much lower temperatures (typically 130°) than those used for the oxidation or the dehydrogenation of ethanol (approximately 500°C for the oxidation and 250°C for the dehydrogenation).

Ethylene oxidation is carried out through oxidation-reduction (redox). The overall reaction is the oxidation of ethylene by oxygen as represented by:

The Wacker process uses an aqueous solution of palladium(II) chloride, copper(II) chloride catalyst system. In the course of the reaction, the Pd2+ ions are reduced to Pd metal, and ethylene is oxidized to acetaldehyde:

The formed Pd° is then reoxidized by the action of Cu(II) ions, which are reduced to Cu(I) ions:

The oxidation reaction may be carried out in a single-stage or a twostage process. In the single-stage, ethylene, oxygen, and recycled gas are fed into a vertical reactor containing the catalyst solution. Heat is controlled by boiling off some of the water. The reaction conditions are approximately 130°C and 3 atmospheres. In the two-stage process, the reaction occurs under relatively higher pressure (approximately 8 atmospheres) to ensure higher ethylene conversion. The reaction temperature is approximately 130°C. The catalyst solution is then withdrawn from the

reactor to a tube-oxidizer to effect the oxidation of the catalyst at approximately 10 atmospheres. The yield of acetaldehyde from either process is about 95%. By-products from this reaction include acetic acid, ethyl chloride, chloroacetaldehyde, and carbon dioxide.

The Wacker reaction can also be carried out for other olefins with terminal double bonds. With propene, for example, approximately 90% yield of acetone is obtained. l-Butene gave approximately 80% yield of methyl ethyl ketone.

Acetaldehyde is an intermediate for many chemicals such as acetic acid, n-butanol, pentaerithritol, and polyacetaldehyde.

|

|

|

|

دراسة يابانية لتقليل مخاطر أمراض المواليد منخفضي الوزن

|

|

|

|

|

|

|

اكتشاف أكبر مرجان في العالم قبالة سواحل جزر سليمان

|

|

|

|

|

|

|

اتحاد كليات الطب الملكية البريطانية يشيد بالمستوى العلمي لطلبة جامعة العميد وبيئتها التعليمية

|

|

|