الفيزياء الكلاسيكية

الفيزياء الكلاسيكية

الكهربائية والمغناطيسية

الكهربائية والمغناطيسية

علم البصريات

علم البصريات

الفيزياء الحديثة

الفيزياء الحديثة

النظرية النسبية

النظرية النسبية

الفيزياء النووية

الفيزياء النووية

فيزياء الحالة الصلبة

فيزياء الحالة الصلبة

الليزر

الليزر

علم الفلك

علم الفلك

المجموعة الشمسية

المجموعة الشمسية

الطاقة البديلة

الطاقة البديلة

الفيزياء والعلوم الأخرى

الفيزياء والعلوم الأخرى

مواضيع عامة في الفيزياء

مواضيع عامة في الفيزياء|

Read More

Date: 14-4-2016

Date: 16-3-2016

Date: 10-3-2016

|

POWER SUPPLIES

Whereas HeNe lasers operate at relatively high voltages (1000 to 1500 V) and low currents (3 to 8 mA), ion lasers operate at much high currents (10 to 40 A) and relatively low voltages (90 to 300 V). Even the smallest air-cooled argon-ion laser with 10 A of discharge current and 90 V across the plasma tube represents a power dissipation of 900 W (as opposed to a HeNe tube, which may dissipate only 5 or 6 W). The design of an ion laser supply, then, is radically different from that of a HeNe laser.

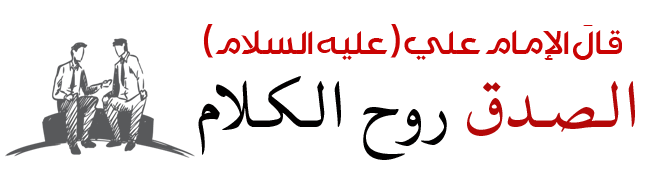

The power supplies of most ion lasers, large or small, simply rectify the incoming AC line directly into DC current, sparing the expense of a large transformer. Power supplies for small air-cooled lasers operating in North America, for example, frequently take ordinary 110 V AC wall current and rectify it to about 155 V DC. This DC current is passed through a small ballast resistance (for the same reasons as in the HeNe laser) and through the tube. Large-frame lasers frequently run on three-phase current of higher voltages, which is advantageous since longer tubes present a greater voltage loss (whereas a small air-cooled ion tube might have 100 V across it when operating, a large-frame 7-W argon might require 260 V). So most large ions (> ½ W for an argon) use three-phase power that is rectified into DC. The advantage of three-phase power (aside from lower average currents per phase and higher voltages because of the service 208 V is standard) is that the capacitor bank which serves to smooth the DC current may be much smaller. As illustrated in Figure 1.1, when three-phase power is used, the rectified line voltage never crosses zero and varies only 14% or so during the 60-Hz power cycle, whereas single-phase rectifiers cross zero volts 120 times per second. A single-phase system, then, requires larger capacitors to supply current during these zero-cross intervals, whereas a three-phase system can be made with much smaller capacitors.

Because of the low DC resistance of the plasma itself (a tube consuming 10 A at 100 V represents an effective resistance of only 1 Ω), the plasma tube essentially acts as a dead short to the power supply, so DC current regulation is almost always required this, in addition to a series ballast resistance, which is frequently 1 Ω or

Figure 1.1. Single- and three-phase rectifiers.

less. In many lasers current regulation is accomplished by a bank of transistors in what is called the series pass or linear pass bank regulator. Many transistors are used in parallel since it is impossible to find a single transistor that will handle the current required. On a large-frame ion laser, these transistors are mounted on a heatsink cooled by the same water as that used to cool the plasma tube. Some smaller lasers (e.g., air-cooled types) use efficient switch mode regulators.

Having a heated cathode, a low-voltage (2.5 to 3 V), high-current (10 to 25 A) source is required as well as the main supply. This is usually supplied by a center-tapped AC transformer not only because it is inexpensive but also because an AC source (with the main DC from the power supply feeding the center tap of the transformer) ensures that the plasma is distributed over both ends of the filament, prolonging its lifetime. As in the HeNe laser, the main supply voltage (between 155 and 400 V DC) is insufficient to start the plasma; a starting pulse of around 10 kV is required. Because of the high currents in the supply, though, a simple multiplier with blocking diodes will not work here, so a pulse transformer in series with the anode is used to generate the high voltage required. These starting transformers are mounted close to the plasma tube. On a small air-cooled laser they are often mounted on a circuit board beside the tube, while on a large-frame ion laser they are mounted on the side of the magnet or immediately under the tube.

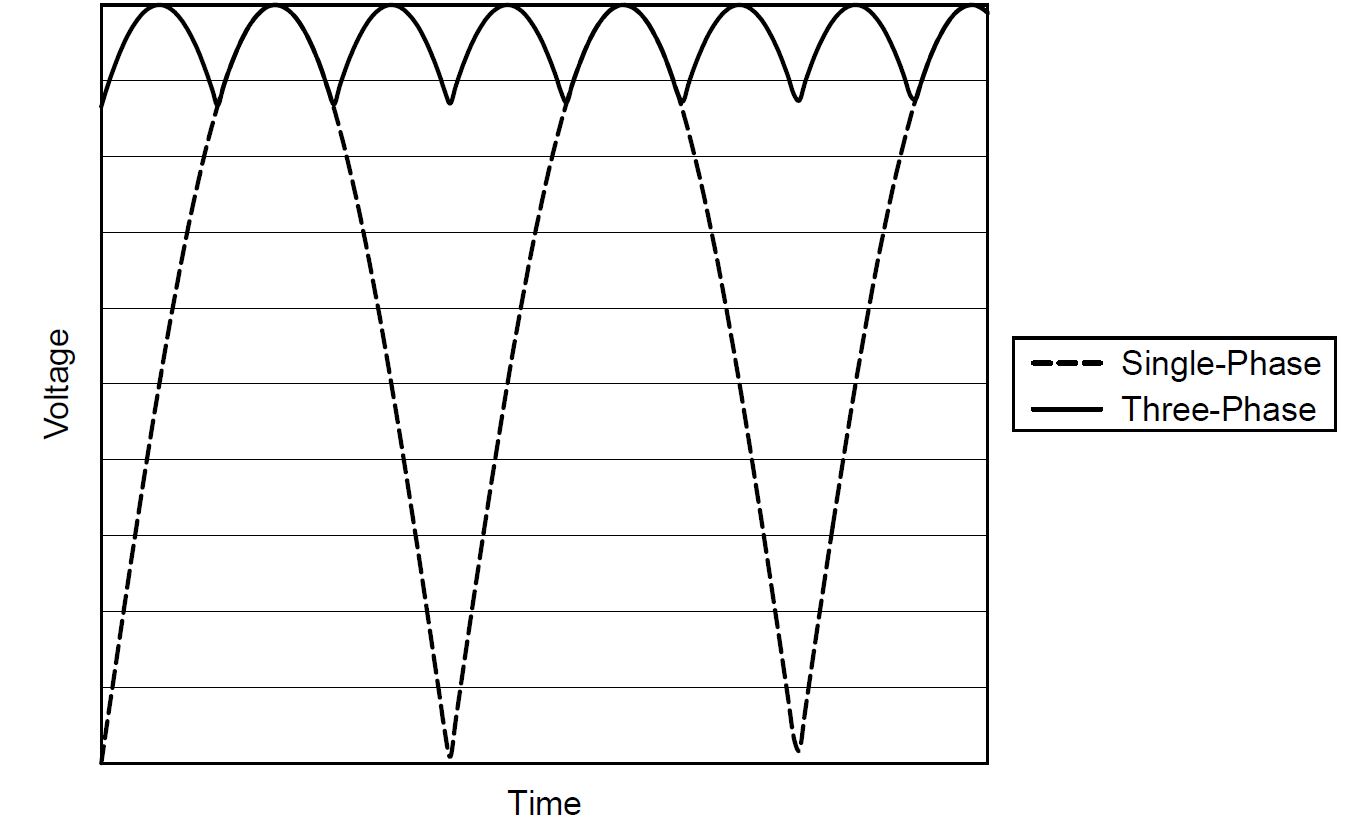

A block diagram showing essential components of an ion laser power supply is depicted in Figure 1.2. The rectifier converts AC to DC; in this case a single phase bridge is shown, but on a large-frame laser using three-phase power, six diodes would be used. The DC current is then smoothed by capacitor C1, providing a constant DC voltage. Current flows from the DC supply through ballast resistor R1 and the secondary winding of the starting transformer. To start the laser tube a pulse

Figure 1.2. Ion laser supply.

of a few hundred volts would be applied to the primary of the transformer, which is stepped up to about 10 kV on the secondary, which then appears across the plasma tube, ionizing the gas inside and initiating the discharge. Current flows through the laser tube to the heated cathode, which is powered by a center-tapped transformer. Current passes from the transformer through the current regulator (the series pass bank) and back to the main DC supply.

Many laser supplies allow the user to select constant-current or constant-light mode. In constant-light mode, current through the tube is adjusted automatically to obtain a constant output power (which would otherwise drift slowly as the plasma tube heats). A small portion of the output beam from the laser is sampled by a photocell or photodiode and a control loop adjusts current accordingly via the regulator.

|

|

|

|

تفوقت في الاختبار على الجميع.. فاكهة "خارقة" في عالم التغذية

|

|

|

|

|

|

|

أمين عام أوبك: النفط الخام والغاز الطبيعي "هبة من الله"

|

|

|

|

|

|

|

قسم شؤون المعارف ينظم دورة عن آليات عمل الفهارس الفنية للموسوعات والكتب لملاكاته

|

|

|