علم الكيمياء

علم الكيمياء

الكيمياء التحليلية

الكيمياء التحليلية

الكيمياء الحياتية

الكيمياء الحياتية

الكيمياء العضوية

الكيمياء العضوية

الكيمياء الفيزيائية

الكيمياء الفيزيائية

الكيمياء اللاعضوية

الكيمياء اللاعضوية

مواضيع اخرى في الكيمياء

مواضيع اخرى في الكيمياء

الكيمياء الصناعية

الكيمياء الصناعية |

Read More

Date: 29-8-2017

Date: 30-7-2017

Date: 28-8-2017

|

Fluid Coking

In the fluid coking process, part of the coke produced is used to provide the process heat. Cracking reactions occur inside the heater and the fluidized-bed reactor. The fluid coke is partially formed in the heater. Hot coke slurry from the heater is recycled to the fluid reactor to provide the heat required for the cracking reactions. Fluid coke is formed by spraying the hot feed on the already-formed coke particles. Reactor temperature is about 520°C, and the conversion into coke is immediate, with complete disorientation of the crystallites of product coke. The burning process in fluid coking tends to concentrate the metals, but it does not reduce the sulfur content of the coke. Fluid coking has several characteristics that make it undesirable for most petroleum coke markets.

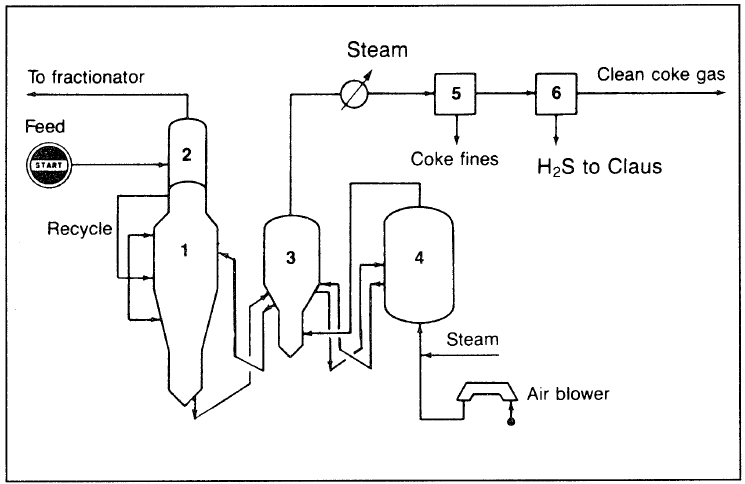

Flexicoking, on the other hand, integrates fluid coking with coke gasification. Most of the coke is gasified. Flexicoking gasification produces a substantial concentration of the metals in the coke product. Figure 3-4 shows an Exxon flexicoking process.

Figure 3-4. Flow diagram of an Exxon flexicoking unit: (1) reactor, (2) scrubber, (3) heater, (4) gasifier, (5) coke finesremoval, (6) H2S removal.

|

|

|

|

دخلت غرفة فنسيت ماذا تريد من داخلها.. خبير يفسر الحالة

|

|

|

|

|

|

|

ثورة طبية.. ابتكار أصغر جهاز لتنظيم ضربات القلب في العالم

|

|

|

|

|

|

|

قسم شؤون المعارف ووفد من جامعة البصرة يبحثان سبل تعزيز التعاون المشترك

|

|

|