النبات

النبات

الحيوان

الحيوان

الأحياء المجهرية

الأحياء المجهرية

علم الأمراض

علم الأمراض

التقانة الإحيائية

التقانة الإحيائية

التقنية الحيوية المكروبية

التقنية الحيوية المكروبية

التقنية الحياتية النانوية

التقنية الحياتية النانوية

علم الأجنة

علم الأجنة

الأحياء الجزيئي

الأحياء الجزيئي

علم وظائف الأعضاء

علم وظائف الأعضاء

الغدد

الغدد

المضادات الحيوية

المضادات الحيوية|

Read More

Date: 5-1-2021

Date: 9-1-2021

Date: 4-1-2021

|

Choice of Support Material for immobilisation

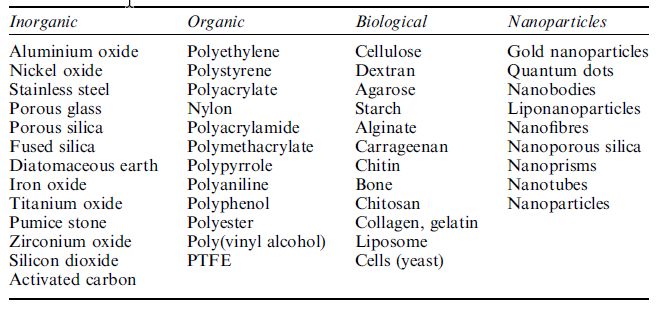

A decision on type of support material for immobilisation will require careful evaluation of the proposed use of the biocatalyst and characteristics of the intended application.Virtually any inorganic, organic or biological material can be used or modified for use as a support material for immobilisation of biocatalysts .

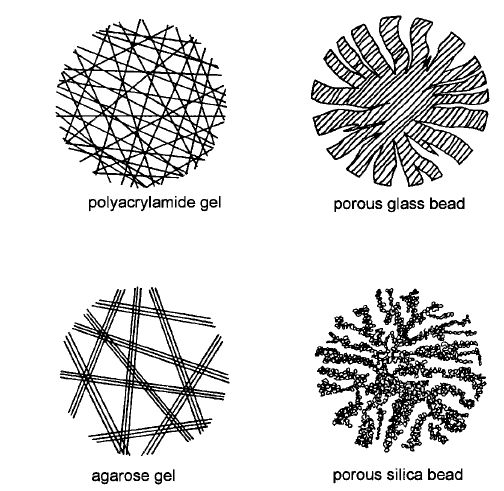

Figure 1 Microstructure of some popular support materials.

The choice of support is influenced by some of the support properties listed below and an evaluation process should help to inform which of the properties are important for the immobilised biocatalyst under consideration:

- Various physical properties of a support may be important, such as strength, non-compression of particles, available surface area, shape/form (beads/sheets/fibres, etc.), non-porous, porous (degree of porosity), pore volume, permeability, density, space for increased biomass, flow rate and pressure drop (Figure 1).

- Chemical features such as hydrophilicity (water binding), inertness towards a biocatalyst and available functional groups for modification, regeneration and re-use of the support may be important.

- Stability characteristics of a support material may influence storage, residual enzyme activity, cell productivity, regeneration of biocatalyst activity, maintenance of cell viability and mechanical integrity of the support.

- A resistance to bacterial/fungal attack, disruption by chemical/pH/temperature/organic solvent, cellular defence mechanisms

Table 1 Some support materials for biocatalyst immobilisation.

(antibodies/killer cells) may be required if a biocatalyst is to operate in a harsh or challenging environment.

-Operational safety considerations such as biocompatibility (immune response), toxicity of component or residual chemical reagents may be important if a support will come into direct or

indirect contact with food, biological fluids, etc.

- There may be health and safety concerns with a support itself or support modification procedures and these may be important for process workers and end product users, and an immobilised biocatalyst may be subject to GRAS (generally recognised as safe) requirements for FDA approval (for food/pharmaceutical/medical applications).

- Key economic concerns may be raised concerning the availability and cost of the support material and/or chemicals, special equipment/reagents, technical skill required, environmental impact, industrial-scale chemical preparation, feasibility for scale-up, continuous processing, effective working life, reusable support and contamination (enzyme/cell-free product).

- Overall reaction characteristics influenced by a support will include flow rate, enzyme/cell loading, catalytic productivity, reaction kinetics, side reactions, multiple enzyme and or cell systems, batch or continuous operation system, reactor type and diffusion limitations on mass transfer of cofactors/substrates/products.

Nanotechnology and Nanoparticle Support Materials

The microelectronics industry and the biosensor industry have both sought greater levels of miniaturisation in their respective technology development and both have now reached a scale where it is possible to work together to produce new products. Engineers have shrunk the dimensions of microfabricated structures to provide faster high-density electronic chips for the electronics industry. Biotechnologists have reduced the volumes required in analytical devices from millilitre to microlitre and nanolitre levels. A convergence can now take place that will allow each sector to take advantage of the unique benefits and technology that each side has developed and create new innovation in the area of nanobiotechnology.Biological materials offer impressive molecular recognition and self-assembly capacity and can be immobilised on non-biological electro/mechanical components to produce new hybrid systems. New research is seeking to use the natural self-assembly characteristics of some biological molecules to assist microfabrication of nanowires for production of two- and three-dimensional nanocircuits for electronics development. A notable benefit of biological intervention in microfabrication is that biological materials allow a greater range of assembly options that can enhance traditional photolithography methods for production of electronic circuits.

Innovation in molecular detection has a focus on moving towards highly multiplexed molecular recognition systems using preconfigured arrays and departing from arrays with fixed recognition sites printed on solid surfaces. This requires new methods of registering and quantifying a specific binding event through electrochemical and/or electronic events and nanotechnology will be instrumental in delivering this objective.

The incorporation of biological components into microelectromechanical systems (MEMS) and implantable devices is achievable, but must be built with biocompatible materials or coated with biocompatible materials.

Immobilisation methods and materials have moved into a new phase to benefit from the opportunities provided by nanotechnology. New support materials such as polymeric microspheres (nanoparticles) have been produced with size ranges from 50 to 10 000nm and used to covalently bind enzymes, antibodies and proteins.Various nanosized objects have been produced, including nanotubes, nanochannels, nanoparticles, nanopores, nanocapacitors, quantum dots, nanorods and nanoprisms.These have increased the range of potential support materials and support configurations that can be used for immobilisation.

Further indications are that nanoparticles may be engineered to provide cell-specific delivery of therapeutic agents such as enzymes, proteins and drugs after injection into the bloodstream. Until relatively recently, most enzymes and cells were immobilised on/ in relatively large structures (micrometre to millimetre scale) to ease the collection, recovery and handling of immobilised enzyme preparations.

New procedures have immobilised biocatalysts to nanoparticles with diameters on the nanometre scale. Reduction in size of support material will generally reduce some of the negative support material effects that limit the effectiveness of a catalytic reaction, particularly in relation to diffusion of substrates and products to and from an enzyme.In addition, nanoparticles composed of or covered with biocompatible materials have potential for in vivo delivery of therapeutic systems. For example, nanoparticles of gold have very low toxicity.

Nanotechnology can provide exciting opportunities for a wide range of significant developments in biotechnology. However, there is one obstacle that requires a solution if the opportunities are to be fully realised and that is energy. Biological systems require and can transduce very specific chemical energy to drive biological systems. Microelectronic systems require and can transduce electrical energy to drive microelectromechanical devices. The two are not easily compatible. An efficient, workable solution that provides a common energy currency to both systems will provide a foundation for new generations of biomicroelectromechanical devices. A solution will facilitate production of a wider range of efficient functional hybrid devices composed of active biological and active non-biological electronic materials each drawing energy from a single energy source.

|

|

|

|

التوتر والسرطان.. علماء يحذرون من "صلة خطيرة"

|

|

|

|

|

|

|

مرآة السيارة: مدى دقة عكسها للصورة الصحيحة

|

|

|

|

|

|

|

نحو شراكة وطنية متكاملة.. الأمين العام للعتبة الحسينية يبحث مع وكيل وزارة الخارجية آفاق التعاون المؤسسي

|

|

|