7:58:28

7:58:28  2026-02-12

2026-02-12  40

40

A newly developed fiber-optic microphone demonstrates how light-based sensing can overcome the limitations of conventional electronics in extreme environments.

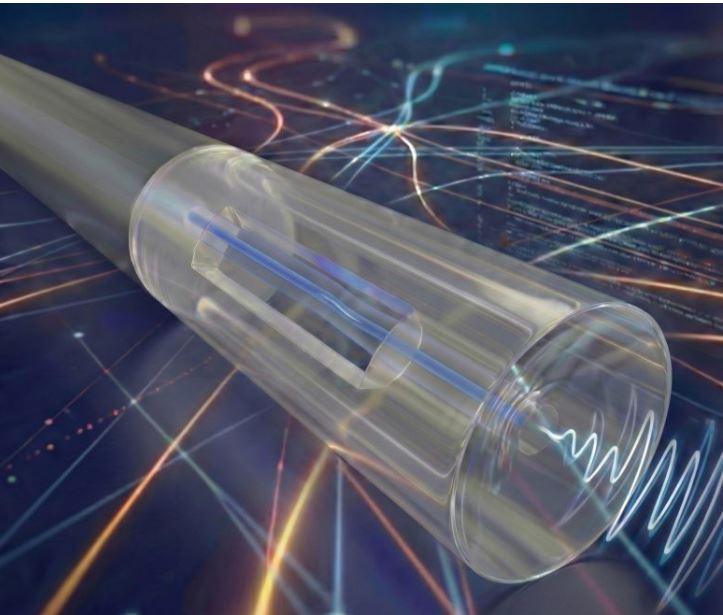

A team of researchers has built a microphone so small it fits inside a strand of pure silica fiber, yet it can pick up ultrasound far above the limits of human hearing. Because the device is made from glass rather than electronics, it is designed to keep working in punishing conditions, including temperatures up to 1,000 °C.

One long-term goal is to place it inside high-voltage transformers so it can detect early signs of trouble before failures cascade into outages.

“Conventional electronic sensors often fail under thermal stress or suffer from severe signal interference,” said Xiaobei Zhang, a member of the research team from Shanghai University. “Our all-fiber microphone can survive in hazardous environments and is completely immune to electromagnetic interference while remaining sensitive enough to hear the subtle early warning signals of equipment failure.”

Writing in the Optica Publishing Group journal Optics Express, the researchers describe a microphone that responds to frequencies ranging from 40 kHz to 1.6 MHz. Instead of relying on a large external casing like traditional microphones, the entire sensing system is built directly into an optical fiber with a diameter of just 125 microns.

“Our all-fiber microphone can be placed directly inside voltage transformers to listen for tiny internal electrical sparks in real-time, preventing blackouts or explosions and keeping our power supply safe,” said Zhang. “The microphone’s incredible durability and wide hearing range make it ideal for everything from industrial testing and medical imaging to monitoring aerospace engines and providing early natural disaster alerts.”

Detecting sound with light

In this study, the researchers concentrated on identifying partial discharge inside high-voltage transformers. Partial discharge refers to small electrical faults that can indicate developing problems well before large-scale failures spread across the power grid. Capturing these signals directly within operating equipment is extremely challenging because of intense heat and strong electromagnetic interference, which limits the effectiveness of conventional sensors.

To address this problem, the team developed a fiber-based microphone that relies on the photoelastic effect. This phenomenon allows mechanical changes, such as tiny vibrations, to alter the refractive index of light traveling through the fiber, making it possible to detect sound optically.

The microphone uses a custom sensing structure that includes a vibration-sensitive membrane and a glass micro beam suspended inside a single mode optical fiber. Together, these elements form a Fabry-Pérot interferometer capable of measuring extremely small vibrations, including those generated by electrical discharge events.

Creating this suspended structure within such a narrow fiber required a highly precise fabrication method. The researchers used picosecond laser-induced chemical etching, an advanced process that enables the formation of detailed micro and nanostructures deep inside solid materials.

Performing across extremes

“The entire interferometric structure is integrated directly within a hair-thin fiber,” said Zhang. “This self-packaged monolithic design enables seamless deployment in high-temperature and space-constrained environments without needing any additional protection.”

The researchers tested the microphone in a 1000°C furnace for 100 minutes, finding that it remained stable and continued to transmit clear signals during this time. They also demonstrated the sensor’s acoustic performance across an ultra-wide range of 40 kHz to 1.6 MHz, verifying its ability to detect sounds in both air and underwater environments.

Looking ahead, the researchers plan to integrate acoustic metamaterials into the device to push the boundaries of sensitivity even further. They also plan to use a multi-laser additive and subtractive manufacturing platform, combining silica 3D printing with ultrafast laser micromachining, to create ultra-robust, all-silica packaging that will significantly enhance both the sensing and mechanical performance of the microphone. This will make it possible to install the microphone inside real-world industrial equipment, like running power transformers, and to survive long-term in extreme conditions.

Reality Of Islam |

|

A newly dev

Get ready f

Researchers

A new metas

9:3:43

9:3:43

2018-11-05

2018-11-05

10 benefits of Marriage in Islam

7:5:22

7:5:22

2019-04-08

2019-04-08

benefits of reciting surat yunus, hud &

9:45:7

9:45:7

2018-12-24

2018-12-24

advantages & disadvantages of divorce

11:35:12

11:35:12

2018-06-10

2018-06-10

6:0:51

6:0:51

2018-10-16

2018-10-16

1:16:44

1:16:44

2018-05-14

2018-05-14

2:2:13

2:2:13

2022-10-08

2022-10-08

9:30:2

9:30:2

2021-11-12

2021-11-12

8:21:9

8:21:9

2018-06-21

2018-06-21

12:10:56

12:10:56

2022-11-17

2022-11-17

a hero waters thirsty wild animals

9:4:9

9:4:9

2022-01-06

2022-01-06

1:38:41

1:38:41

2021-12-08

2021-12-08

5:41:46

5:41:46

2023-03-18

2023-03-18

| LATEST |