تاريخ الفيزياء

علماء الفيزياء

الفيزياء الكلاسيكية

الميكانيك

الديناميكا الحرارية

الكهربائية والمغناطيسية

الكهربائية

المغناطيسية

الكهرومغناطيسية

علم البصريات

تاريخ علم البصريات

الضوء

مواضيع عامة في علم البصريات

الصوت

الفيزياء الحديثة

النظرية النسبية

النظرية النسبية الخاصة

النظرية النسبية العامة

مواضيع عامة في النظرية النسبية

ميكانيكا الكم

الفيزياء الذرية

الفيزياء الجزيئية

الفيزياء النووية

مواضيع عامة في الفيزياء النووية

النشاط الاشعاعي

فيزياء الحالة الصلبة

الموصلات

أشباه الموصلات

العوازل

مواضيع عامة في الفيزياء الصلبة

فيزياء الجوامد

الليزر

أنواع الليزر

بعض تطبيقات الليزر

مواضيع عامة في الليزر

علم الفلك

تاريخ وعلماء علم الفلك

الثقوب السوداء

المجموعة الشمسية

الشمس

كوكب عطارد

كوكب الزهرة

كوكب الأرض

كوكب المريخ

كوكب المشتري

كوكب زحل

كوكب أورانوس

كوكب نبتون

كوكب بلوتو

القمر

كواكب ومواضيع اخرى

مواضيع عامة في علم الفلك

النجوم

البلازما

الألكترونيات

خواص المادة

الطاقة البديلة

الطاقة الشمسية

مواضيع عامة في الطاقة البديلة

المد والجزر

فيزياء الجسيمات

الفيزياء والعلوم الأخرى

الفيزياء الكيميائية

الفيزياء الرياضية

الفيزياء الحيوية

الفيزياء العامة

مواضيع عامة في الفيزياء

تجارب فيزيائية

مصطلحات وتعاريف فيزيائية

وحدات القياس الفيزيائية

طرائف الفيزياء

مواضيع اخرى

Electrodeposition

المؤلف:

J. M. D. COEY

المصدر:

Magnetism and Magnetic Materials

الجزء والصفحة:

548

5-3-2021

2832

Electrodeposition

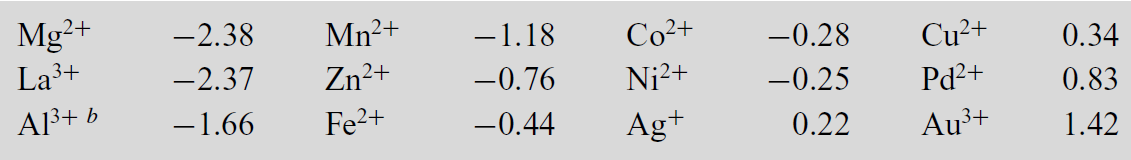

Electrodeposition is a convenient and well-established means of producing thin films of ferromagnetic metals and alloys such as Co–Fe or Ni–Fe. Permalloy is a favourite. Aqueous solutions of the metal ions, including special chemical additives to promote smoothness of the plated films, are used in an electrochemical cell which is agitated to ensure efficient plating when the current at a given potential is mass-transport limited. Conditions are chosen to ensure that any hydrogen evolved at the cathode due to the reduction of water does not spoil the quality of the deposit. Metal is deposited on the cathode, provided the applied voltage exceeds the reduction potential. For example, the reduction of nickel according to the reaction Ni2+ → Ni + 2e occurs at −0.25 V relative to a reference hydrogen electrode reaction. Some standard reduction potentials are listed in Table 1.

Metals which are not too electronegative to plate include the late transition metals from Fe to Zn, Rh, Pd, Pt as well as the noble metals Cu, Ag, Au and several others, but unfortunately not the early transition metals or the

Table 1. Standard reduction potentials (volts) in aqueous solution

rare-earths. The deposition rate depends on the overpotential, and it is possible to deposit alloy films such as permalloy Ni78Fe22 from a bath containing appropriate concentrations of Fe2+ and Ni2+. The atomic composition of the bath will be quite different from the target composition of the alloy. An easy direction of magnetization of the soft magnetic film can be achieved by applying a magnetic field during deposition. The effect is similar to magnetic field annealing – a slight texture is established with Fe–Fe pairs aligned parallel to the applied field direction.

Nanowires can be obtained by plating into a porous insulating membrane which is metallized on the back. Microporous alumina with a dense hexagonal array of parallel pores is often used. Multilayers can be obtained from a single bath by toggling the deposition potential between two values. For example, Co–Cu layers can be deposited from a bath that is a 25m Msolution of Cu2+ and a 1Msolution of Co2+. At 0.1V, for example, only copper will be deposited, whereas at −0.4V both Co and Cu will be reduced. However, the concentration of Cu in the bath is so low that the alloy is then predominantly Co.

Magnetically hard rare-earth alloys such as SmCo5 cannot be plated from aqueous solutions. At the large negative voltages required, the current will consist almost entirely of protons from the water. However, phases such as CoPt can be obtained. As deposited, these alloys have a disordered fcc structure, but they only adopt the tetragonal L10 structure and develop hysteresis after annealing at about 900 K.

الاكثر قراءة في المغناطيسية

الاكثر قراءة في المغناطيسية

اخر الاخبار

اخر الاخبار

اخبار العتبة العباسية المقدسة

الآخبار الصحية

قسم الشؤون الفكرية يصدر كتاباً يوثق تاريخ السدانة في العتبة العباسية المقدسة

قسم الشؤون الفكرية يصدر كتاباً يوثق تاريخ السدانة في العتبة العباسية المقدسة "المهمة".. إصدار قصصي يوثّق القصص الفائزة في مسابقة فتوى الدفاع المقدسة للقصة القصيرة

"المهمة".. إصدار قصصي يوثّق القصص الفائزة في مسابقة فتوى الدفاع المقدسة للقصة القصيرة (نوافذ).. إصدار أدبي يوثق القصص الفائزة في مسابقة الإمام العسكري (عليه السلام)

(نوافذ).. إصدار أدبي يوثق القصص الفائزة في مسابقة الإمام العسكري (عليه السلام)