10:32:7

10:32:7  2023-03-04

2023-03-04  1135

1135

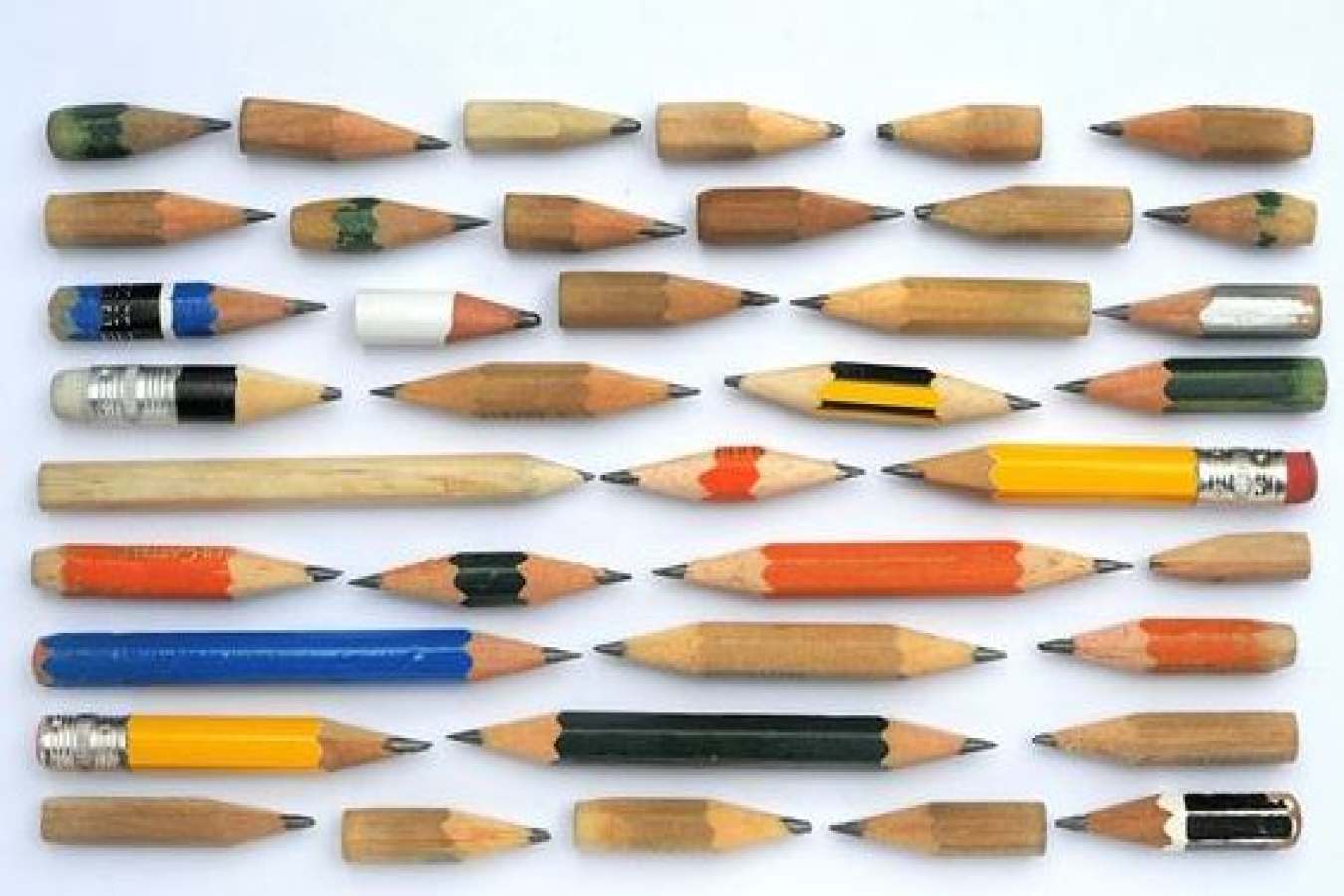

Billions of pencils are produced worldwide every year.

The process is fully automated.

First, a mixture of clay and graphite is crushed and pressed.

The soft mixture is extruded through a nozzle, to form the long string of the pencil's core.

The lead rods are dried and curd in an oven at 815 degree Celsius.

The extreme heat makes the lead smooth and hard.

The next step is to prepare the wood for the lead.

the wood must be soft enough to sharpen, but not so soft that it'll bend while writing.

Most pencils are made of cedar or basswood trees.

The wood is pre-cut into slats.

Each slat goes through the groover machine, which cuts grooves into the surface of the wood.

The grooves are then filled with a special elastic glue, that acts as a cushion for the graphite rods.

And then, it is time to add the lead.

A second slate is placed on top of the first slate, sandwiching the lead in the middle.

A mechanized plunger squeezes it together.

A cutter then slices it into the desired pencil shape.

Then, it is time to apply a coat of paint.

Each pencil goes through a lacquering head, where it is coated with multiple layers of paint.

The final step is adding the rubber eraser.

Before being sent off to the rest of the world, pencils wait in the drying room for a quality check.

After sharpening and visual control, they're ready for their new users.

Reality Of Islam |

|

Researchers

A well-know

Scientists

As AI-power

9:3:43

9:3:43

2018-11-05

2018-11-05

10 benefits of Marriage in Islam

7:5:22

7:5:22

2019-04-08

2019-04-08

benefits of reciting surat yunus, hud &

9:45:7

9:45:7

2018-12-24

2018-12-24

advantages & disadvantages of divorce

11:35:12

11:35:12

2018-06-10

2018-06-10

6:0:51

6:0:51

2018-10-16

2018-10-16

3:18:29

3:18:29

2022-12-24

2022-12-24

2:34:48

2:34:48

2022-01-18

2022-01-18

bahlool & the throne of haroun rashid

8:20:35

8:20:35

2018-06-21

2018-06-21

7:26:19

7:26:19

2022-04-08

2022-04-08

10:55:53

10:55:53

2022-06-13

2022-06-13

a hero waters thirsty wild animals

9:4:9

9:4:9

2022-01-06

2022-01-06

1:34:8

1:34:8

2022-02-01

2022-02-01

5:41:46

5:41:46

2023-03-18

2023-03-18

| LATEST |