علم الكيمياء

تاريخ الكيمياء والعلماء المشاهير

التحاضير والتجارب الكيميائية

المخاطر والوقاية في الكيمياء

اخرى

مقالات متنوعة في علم الكيمياء

كيمياء عامة

الكيمياء التحليلية

مواضيع عامة في الكيمياء التحليلية

التحليل النوعي والكمي

التحليل الآلي (الطيفي)

طرق الفصل والتنقية

الكيمياء الحياتية

مواضيع عامة في الكيمياء الحياتية

الكاربوهيدرات

الاحماض الامينية والبروتينات

الانزيمات

الدهون

الاحماض النووية

الفيتامينات والمرافقات الانزيمية

الهرمونات

الكيمياء العضوية

مواضيع عامة في الكيمياء العضوية

الهايدروكاربونات

المركبات الوسطية وميكانيكيات التفاعلات العضوية

التشخيص العضوي

تجارب وتفاعلات في الكيمياء العضوية

الكيمياء الفيزيائية

مواضيع عامة في الكيمياء الفيزيائية

الكيمياء الحرارية

حركية التفاعلات الكيميائية

الكيمياء الكهربائية

الكيمياء اللاعضوية

مواضيع عامة في الكيمياء اللاعضوية

الجدول الدوري وخواص العناصر

نظريات التآصر الكيميائي

كيمياء العناصر الانتقالية ومركباتها المعقدة

مواضيع اخرى في الكيمياء

كيمياء النانو

الكيمياء السريرية

الكيمياء الطبية والدوائية

كيمياء الاغذية والنواتج الطبيعية

الكيمياء الجنائية

الكيمياء الصناعية

البترو كيمياويات

الكيمياء الخضراء

كيمياء البيئة

كيمياء البوليمرات

مواضيع عامة في الكيمياء الصناعية

الكيمياء الاشعاعية والنووية

HYDROGEN

المؤلف:

sami matar & Lewis. F. Hatch

المصدر:

Chemistry of PETROCHEMICAL PROCESSES

الجزء والصفحة:

p 111

1-8-2017

1450

HYDROGEN

Hydrogen is the lightest known element. Although only found in the free state in trace amounts, it is the most abundant element in the universe and is present in a combined form with other elements. Water, natural gas, crude oils, hydrocarbons, and other organic fossil materials are major sources of hydrogen.

Hydrogen has been of great use to theoretical investigation. The structure of the atom developed by Bohr (Nobel Prize Winner 1922) was based on a model of the hydrogen atom. Chemically, hydrogen is a very reactive element. Obtaining hydrogen from its compounds is an energyextensive process. To decompose water into hydrogen and oxygen, an energy input equal to an enthalpy change of +286 KJ/mol is required :

Electrolysis, and thermochemical and photochemical decomposition of water followed by purification through diffusion methods are expensive processes to produce hydrogen.

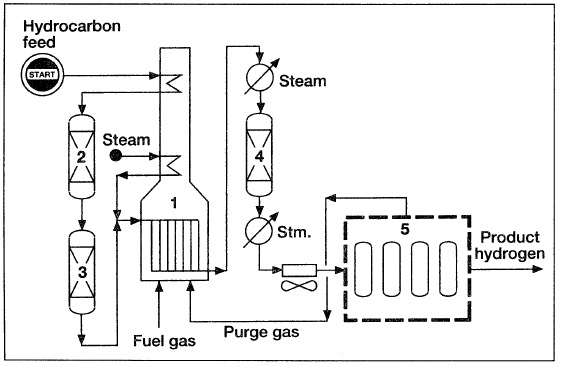

The most economical way to produce hydrogen is by steam reforming petroleum fractions and natural gas (Figure 4-1). In this process, two major sources of hydrogen (water and hydrocarbons) are reacted to produce a mixture of carbon monoxide and hydrogen (synthesis gas).

Hydrogen can then be separated from the mixture after shift converting carbon monoxide to carbon dioxide. Carbon oxides are removed by passing the mixture through a pressure swing adsorption system. Recently, a new process has been developed to manufacture hydrogen by steam reforming methanol. In this process, an active catalyst is used to decompose methanol and shift convert carbon monoxide to carbon dioxide. The produced gas is cooled, and carbon dioxide is removed:

Figure 1.1. A process for producing hydrogen by steam reforming of hydrocarbons: (1) reforming furnace (2,3) purification section, (4) shift converter, (5) pressure swing adsorption.

This process is used to produce relatively small quantities (0.18–1.8 MMscfd) of highly pure hydrogen when methanol is available at a reasonable price. In the petroleum refining industry, hydrogen is essentially obtained from catalytic naphtha reforming, where it is a coproduct with reformed gasoline.

The use of hydrogen in the chemical and petroleum refining industries is of prime importance. Hydrogen is essentially a hydrogenating agent. For example, it is used with vegetable oils and fats to reduce unsaturated esters (triglycerides). It is also a reducing agent for sulfide ores such as zinc and iron sulfides (to get the metals from their ores).

Hydrogen use in the petroleum refining includes many processing schemes such as hydrocracking, hydrofinishing of lube oils, hydrodealkylation and hydrodesulfurization of petroleum fractions and residues. Hydrocracking of petroleum resids is becoming more important to produce lighter petroleum distillates of low sulfur and nitrogen content to meet stringent government-mandated product specifications to control pollution.

In the petrochemical field, hydrogen is used to hydrogenate benzene to cyclohexane and benzoic acid to cyclohexane carboxylic acid. These compounds are precursors for nylon production. It is also sed to selectively hydrogenate acetylene from C4 olefin mixture. As a constituent of synthesis gas, hydrogen is a precursor for ammonia, methanol, Oxo alcohols, and hydrocarbons from Fischer Tropsch processes. The direct use of hydrogen as a clean fuel for automobiles and buses is currently being evaluated compared to fuel cell vehicles that use hydrocarbon fuels which are converted through on-board reformers to a hydrogen-rich gas. Direct use of H2 provides greater efficiency and environmental benefits.

Due to the increasing demand for hydrogen, many separation techniques have been developed to recover it from purge streams vented from certain processing operations such as hydrocracking and hydrotreating.

In addition to hydrogen, these streams contain methane and other light hydrocarbon gases. Physical separation techniques such as adsorption, diffusion, and cryogenic phase separation are used to achieve this goal.

Adsorption is accomplished using a special solid that preferentially adsorbs hydrocarbon gases, not hydrogen. The adsorbed hydrocarbons are released by reducing the pressure. Cryogenic phase separation on the other hand, depends on the difference between the volatilities of the components at the low temperatures and high pressures used. The vapor phase is rich in hydrogen, and the liquid phase contains the hydrocarbons.

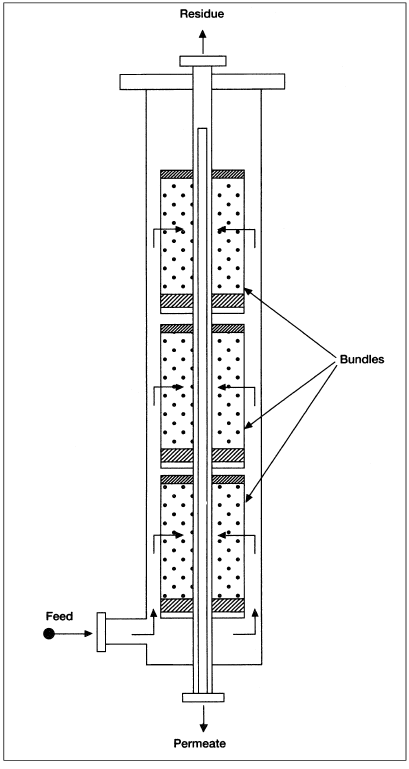

Hydrogen is separated from the vapor phase at high purity. Diffusion separation processes depend on the permeation rate for gas mixtures passing through a special membrane. The permeation rate is a function of the type of gas feed, the membrane material, and the operating conditions. Gases with smaller molecular sizes such as helium and hydrogen permeate membranes more readily than larger molecules such as methane and ethane.4 An example of membrane separator is the hollow fiber type shown in Figure 1.2. After the feed gas is preheated and filtered it enters the membrane separation section. This is made of a permeater vessel containing 12-inch diameter bundles (resemble filter cartridges) and consists of millions of hollow fibers. The gas mixture is distributed in the annulus between the fiber bundle and the vessel wall.

Hydrogen, being more permeable, diffuses through the wall of the hollow fiber and exits at a lower pressure. The less permeable hydrocarbons flow around the fiber walls to a perforated center tube and exit at approximately feed pressure. It has been reported that this system can deliver a reliable supply of 95+% pure hydrogen from off-gas streams having as low as 15% H2.

Figure 1.2. Permeator for gas separation

الاكثر قراءة في البترو كيمياويات

الاكثر قراءة في البترو كيمياويات

اخر الاخبار

اخر الاخبار

اخبار العتبة العباسية المقدسة

الآخبار الصحية

قسم الشؤون الفكرية يصدر كتاباً يوثق تاريخ السدانة في العتبة العباسية المقدسة

قسم الشؤون الفكرية يصدر كتاباً يوثق تاريخ السدانة في العتبة العباسية المقدسة "المهمة".. إصدار قصصي يوثّق القصص الفائزة في مسابقة فتوى الدفاع المقدسة للقصة القصيرة

"المهمة".. إصدار قصصي يوثّق القصص الفائزة في مسابقة فتوى الدفاع المقدسة للقصة القصيرة (نوافذ).. إصدار أدبي يوثق القصص الفائزة في مسابقة الإمام العسكري (عليه السلام)

(نوافذ).. إصدار أدبي يوثق القصص الفائزة في مسابقة الإمام العسكري (عليه السلام)